Iron Ore Processing: From Extraction to Manufacturing - Mining

2024年4月26日 Iron ore, a naturally occurring mineral composed primarily of iron oxides, is mined and processed to extract iron for various industrial applications. This article provides a comprehensive overview of the iron ore processing journey, from extraction to manufacturing,

The six main steps of iron ore processing - Multotec

Six steps to process iron ore. 1. Screening. We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A static

Iron Ore Processing, General - SpringerLink

2022年10月20日 Making iron and steel from iron ore requires a long process of mining, crushing, separating, concentrating, mixing, agglomeration (sintering and pelletizing), and

Introduction: Overview of the global iron ore industry

2022年1月1日 This chapter first provides an overview of world iron ore production and trade, as well as reserves and resources, followed by a summary of the key mining operations in the top

Iron ore - Wikipedia

Iron ore mining methods vary by the type of ore being mined. There are four main types of iron ore deposits worked currently, depending on the mineralogy and geology of the ore deposits. These are magnetite, titanomagnetite, massive

Iron Ore Processing, General

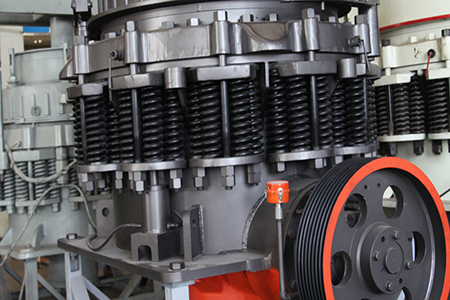

Making iron and steel from iron ore requires a long process of mining, crushing, separating, concentrating, mixing, agglomeration (sintering and pelletizing), and shipping to steel mills.

Iron processing - Ores, Smelting, Refining Britannica

China, Brazil, Australia, Russia, and Ukraine are the five biggest producers of iron ore, but significant amounts are also mined in India, the United States, Canada, and Kazakhstan.

Iron ore extraction techniques - ScienceDirect

2015年1月1日 This chapter has sought to demonstrate, using case study examples, how iron ore mining has developed from a small-scale industry feeding local steel plants on a regional

Iron Ore: Mineralogy, Processing and Environmental Sustainability ...

2021年12月2日 As an essential input for the production of crude steel, iron ore feeds the world's largest trillion-dollar-a-year metal market and is the backbone of the global infrastructure. The

Processing - Karara Mining

Magnetite ore known as Run-of-Mine ... Karara comprises a large-scale, long-life magnetite orebody amenable to bulk mining and processing. Magnetite ore has lower iron content (34-36% Fe) than hematite ore (58-64% Fe). It must be

Tonkolili Iron Ore Mine, Sierra Leone, West Africa

2021年6月11日 The Tonkolili iron ore mine covers a 408m² area with an estimated resource capacity of up to 13.7 billion tons of iron ore. Tonkolili mine development The first phase of development included the establishment of a mine, reconstruction of the Pepel Port, 74km of existing railway, and the construction of a new 126km narrow gauge railroad as logistics

Razorback Iron Ore Project Magnetite Mines

Discover Magnetite Mines' flagship Razorback Iron Ore Project, poised to produce high-grade and DR-grade iron ore for low-carbon and zero-carbon steel production. Owned by ASX-listed Magnetite Mines Limited, the project boasts 2 billion tonnes of Probable Ore Reserves and 3.2 billion tonnes of Mineral Resources. Located near Adelaide with access to key infrastructure,

Iron Ore Processing, General

Iron Ore Processing, General 1 Introduction Iron is the world’s most commonly used metal–steel, of which iron ore is the key ... mine plan. To uncover taconite reserves, the mine area is rst “stripped” of the overburden or glacial drift, comprised primarily of rock, clay, and gravel.

RANKED: World’s top 20 biggest iron ore operations

2021年12月23日 Rio Tinto’s iron ore operations in the Pilbara began in 1966, with the Mount Tom Price mine (pictured) part of Hamersley mine complex, opening that year. ( Image courtesy of Wikipedia.

Iron Ore Processing - an overview ScienceDirect Topics

Iron ore processing refers to the techniques used to extract iron from oolitic iron ores, involving processes such as ... Bayan Obo was originally developed as an iron ore mine, and the rare earth concentrates produced were actually the tailings of the iron ore processing and did not put into production until the 1960s. (Gupta and ...

Life cycle assessment of iron ore mining and processing

2015年1月1日 Four Australian mine sites (i.e., Brockman, Paraburdoo, Hopes Down, and Yandicoogina) were chosen for this analysis to derive representative information for the iron ore mining and processing operations in Australia. These mine sites were chosen as they range from small to large iron ore mine sites in terms of production capacity.

Kiruna Iron Ore Mine, Sweden - Mining Technology

2020年8月20日 With an ore body 4km-long, 80m-thick and reaching a depth of 2km, LKAB’s Kiruna is the world’s largest, most modern underground iron ore mine located in northern Sweden. Since mining began at the iron ore operation more than 100 years ago, Luossavaara-Kiirunavaara AB (LKAB) produced over 950Mt of ore, yet only one-third of the original ore body has been

Iron ore - Wikipedia

Hematite, the main iron ore found in Brazilian mines Stockpiles of iron ore pellets like this one are used in steel production. An illustration of iron ore being unloaded at docks in Toledo, Ohio. Iron ores [1] are rocks and minerals from which metallic iron can be economically extracted. The ores are usually rich in iron oxides and vary in color from dark grey, bright yellow, or deep purple ...

Iron Ore Processing, General - SpringerLink

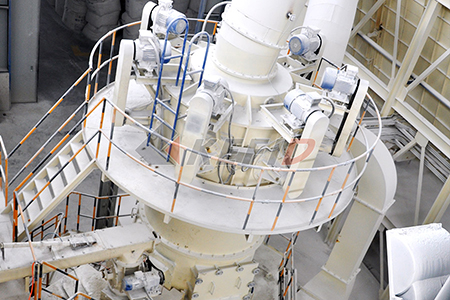

2022年10月20日 Iron ore handling, which may account for 20–50% of the total delivered cost of raw materials, covers the processes of transportation, storage, feeding, and washing of the ore en route to or during its various stages of treatment in the mill.. Since the physical state of iron ores in situ may range from friable, or even sandy materials, to monolithic deposits with hardness of

Iron ore - Wikipedia

Hematite, the main iron ore found in Brazilian mines Stockpiles of iron ore pellets like this one are used in steel production. An illustration of iron ore being unloaded at docks in Toledo, Ohio. Iron ores [1] are rocks and minerals from

Iron ore - Fortescue

Iron Bridge is our magnetite mining operation, located 145km south of Port Hedland. Unlike our hematite operations, Iron Bridge produces a wet concentrate product which is transported to Port Hedland through a 135-kilometre-long specialist slurry pipeline where dewatering and materials handling occurs. It also includes a return water pipeline.

[PDF] Rock mass structural data analysis using image processing ...

Then the discontinuity data collection based on digital image analysis is developed and applied in a case study to several walls of the Choghart iron ore mine. The results obtained show that this method has a very good accuracy in assessing the fine structures, and also it collects data in a much shorter time.

The six main steps of iron ore processing - Multotec

When iron ore is extracted from a mine, it must undergo several processing stages. Six steps to process iron ore. 1. Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage.

Iron Ore production in the Pilbara

Iron Ore production in the Pilbara Activities involved in finding, mining and processing iron ore at our Pilbara operations have been simplified in the following diagram. Rio Tinto operates 11 iron ore mines in the Pilbara and the specific sequence of activities varies from mine to mine. Excellence in planning, scheduling and quality control

Operations Anglo American – Kumba Iron Ore

Sishen mine. Sishen mine, is near the town of Kathu in the Northern Cape Province. Sishen is our flagship operation and one of the largest open pit mines in the world – some 14km long. Sishen mine has sufficient reserves to sustain a 14-year life of mine. The bulk of our iron ore production comes from Sishen mine, with most of it being exported.

Kiruna Iron Ore Mine, Sweden - Mining Technology

2020年8月20日 With an ore body 4km-long, 80m-thick and reaching a depth of 2km, LKAB’s Kiruna is the world’s largest, most modern underground iron ore mine located in northern Sweden. Since mining began at the iron ore operation more than 100 years ago, Luossavaara-Kiirunavaara AB (LKAB) produced over 950Mt of ore, yet only one-third of the original ore body has been

Iron Ore - Rio Tinto

Rio Tinto Iron Ore. We are one of the world’s leading producers of iron ore. Our iron ore operations in the Pilbara comprise a world-class, integrated network of 17 iron ore mines, 4 independent port terminals, a 1,900-kilometre rail network and related infrastructure.. We produce these mainstream iron ore products in Western Australia, including Pilbara Blend, the world's

Kiruna mine - Wikipedia

The Kiruna mine is the largest and most modern underground iron ore mine in the world. [1] [unreliable source?] The mine is located in Kiruna in Norrbotten County, Lapland, Sweden. [1] The mine is owned by Luossavaara-Kiirunavaara AB (LKAB), a large Swedish mining company. In 2018 the mine produced 26.9 million tonnes of iron ore. [2] The Kiruna mine has an ore body

Life cycle assessment of iron ore mining and processing

2015年1月1日 Four Australian mine sites (i.e., Brockman, Paraburdoo, Hopes Down, and Yandicoogina) were chosen for this analysis to derive representative information for the iron ore mining and processing operations in Australia. These mine sites were chosen as they range from small to large iron ore mine sites in terms of production capacity.